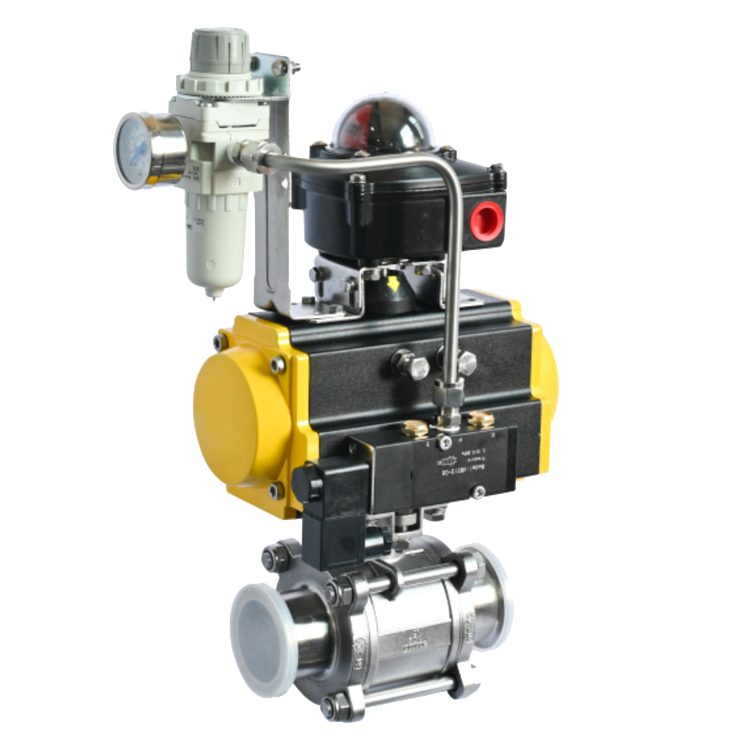

Pneumatic Ball Valve

Pneumatic ball valves provide fast on/off control and tight shutoff for liquids, gases and corrosives. With polymer or stainless bodies, they resist corrosion for long service life. Customizable automation and accessories available.

Description

Our pneumatic ball valves provide reliable shutoff and flow control for liquids, gases, and corrosive media. The spherical ball design allows quick, 90-degree operation between open and closed states. Constructed from stainless steel or engineered polymer materials, these valves resist corrosion for extended service life. Reinforced PTFE or Viton seats ensure tight sealing even after thousands of cycles.

The blow-out proof stem, anti-static feature, and fire-safe design provide added safety. With options for pneumatic actuation and accessories like positioners and solenoids, the valves enable automated on/off control. Various end connections are available, including threaded, flanged, and wafer types.

Contact our engineers to select the optimal size, configuration and accessories based on your application specifications.

Key Features

- Novel and reasonable design

- Rapid opening and closing

- Small operating torque

- Convenient operation

Specifications

Item | Data |

Working temperature | ≤ 100 ºC |

Applicable medium | water, oil and steam nitric acid |

Nominal diameter | DN 50 ~ DN 250 mm |

Nominal pressure | pn1.6, 2.5, 4.0Mpa |

Get Our Brochure

Download our brochure for in-depth details on specifications, custom options, and performance data.

Service WE Offer

From Design Engineering to On-site Support

We provide integrated services spanning design, manufacturing, testing, installation, integration, training, maintenance and technical support throughout the actuator lifecycle.

Our collaboration focuses on product engineering, quality control, performance testing, on-site assistance, staff training, operation guides, and ongoing maintenance. This end-to-end approach ensures efficiency and reliability.

Payment Questions

Frequently Asked Questions

Our actuators can handle quarter-turn valves like ball, butterfly and plug designs, as well as linear globe and gate valves.

Common materials include aluminum, stainless steel. We offer other alloys and coatings for specialized corrosion resistance.

Electric actuators provide more precision control and lower operating costs, but have higher initial costs. Pneumatic types are simpler and more economical.

Yes, we can apply custom finishes and paints to meet any specifications, including harsh chemical environments.

Please keep them in a clean, dry area away from weather elements. Avoid any impacts or contamination.

Our designs meet global standards like ISO, CE, ATEX and others. We can customize to meet many regulations.

Please email [email protected] or call our customer service line. We value all customer inputs.

Manuals can be downloaded from the product pages on our website, or requested from our customer

You need to consider the valve’s torque requirement and stroke length. Our sizing guide provides detailed steps to match your valve specs to the appropriate actuator. Consult our engineers if needed.

Our standard warranty is 12 months from the date of delivery. Extended warranties are available.

Feel free to contact us

Our experts are ready to discuss your specific requirements and recommend customized solutions to optimize your valve and actuator operations.

Contact us today to get our engineering support and customer service.

+86(577)5775 5599